Ultimate Guide to LED Panels

What is an LED light panel?

An LED light panel is a flat panel that uses light-emitting diodes (LEDs) to produce bright and energy-efficient light. LED light panels are commonly used in a variety of settings, such as homes, offices, and commercial spaces.

LED light panels consist of a grid of small LEDs that are mounted on a flat surface, such as a sheet of plastic or glass. The LEDs are arranged in a way that provides even illumination across the entire panel. The panels can come in various sizes, shapes, and colors, and are often used as a source of general or task lighting.

LED light panels offer several advantages over traditional light sources. They consume less energy and produce less heat, making them more cost-effective and safer to use. LED light panels are also long-lasting, with very long lifespans, and they emit a brighter and more uniform light than other light sources.

LED light panels can be used for a wide range of applications, including architectural lighting, photography and videography lighting, signage, and backlighting for displays and televisions. They are also increasingly popular for use in homes and offices as a source of ambient or task lighting, due to their energy efficiency and versatility.

In what different ways can LED light panels be installed?

LED light panels can be installed in a variety of ways, depending on the application and the specific type of panel. Here are some common methods of installing LED light panels:

- Surface mounting: This is the most common method of installing LED light panels. The panel is mounted directly onto the surface of the ceiling or wall using screws or adhesive.

- Recessed mounting: In this method, the LED light panel is mounted into a cutout in the ceiling or wall, creating a flush appearance. Recessed mounting requires a special mounting kit and is often used for architectural lighting or in locations where a low-profile look is desired.

- Suspended mounting: In this method, the LED light panel is hung from the ceiling using cables or wires. This is often used for commercial lighting or as an alternative to recessed lighting.

- Track mounting: LED light panels can be mounted onto a track system, which allows for easy adjustment and repositioning of the panels. This is often used in retail or display settings.

- Backlighting: LED light panels can be used as a backlight for displays, televisions, or signage. The panel is mounted behind the display or sign to create a bright, even glow.

- Portable mounting: Some LED light panels come with a stand or mounting bracket that allows them to be placed on a tabletop or other surface.

The specific method of installation will depend on the application and the type of LED light panel being used. It's important to follow the manufacturer's instructions and consult a professional installer or electrician if you're unsure about how to install your LED light panel.

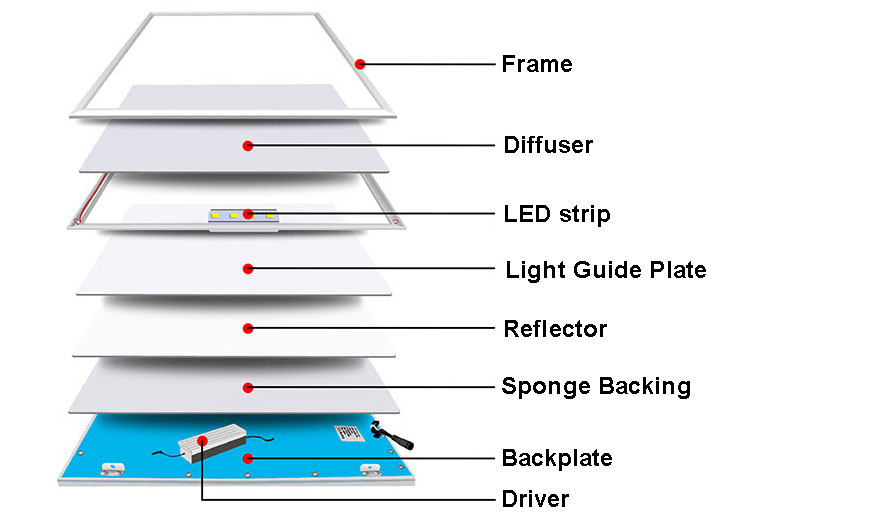

What components are inside an LED panel?

An LED light panel will contain the following components:

- LED chips: These are the individual light-emitting diodes that produce light in an LED light panel. They are typically arranged in a grid pattern on the panel to provide even illumination.

- LED driver: This is an electronic component that regulates the power supply to the LED chips. It converts AC power from the mains into DC power that can be used by the LED chips.

- Heat sink: LED chips produce heat as a byproduct of their operation. A heat sink is used to dissipate this heat and prevent the LED chips from overheating. Heat sinks can be made from a variety of materials, such as aluminum, and are often incorporated into the design of the LED light panel.

- Diffuser: A diffuser is an optional component that can be used to spread the light from the LED chips evenly across the panel. It is typically made from a translucent material such as acrylic or polycarbonate.

- Reflective layer: Some LED light panels have a reflective layer behind the LED chips to increase the brightness and uniformity of the light output.

- Frame: The frame is the outer shell of the LED light panel. It is typically made from aluminum or plastic and provides a mounting surface for the panel.

- Wiring and connectors: Some LED light panels require wiring and connectors to connect the LED driver to the power source. These components may be included with the LED light panel or purchased separately.

- Control system: Some LED light panels come with a control system that allows for dimming, color changing, or other special effects. These systems can be integrated into the panel or installed separately.

- Power supply: LED light panels require a power supply to provide electricity to the LED driver. This can be a built-in power supply or an external power supply.

What different materials Are LED light panels made from?

LED light panels can be made from a variety of materials, depending on the specific application and requirements. Here are some of the most common materials used to make LED light panels:

- Aluminum: Aluminum is a popular material for LED light panel frames because it is lightweight, durable, and has good thermal conductivity. It also has a sleek, modern appearance that is well-suited for architectural lighting applications.

- Acrylic: Acrylic is a type of plastic that is often used as a diffuser material for LED light panels. It is lightweight, easy to shape, and provides good light transmission while diffusing the light evenly.

- Polycarbonate: Polycarbonate is another type of plastic that is commonly used as a diffuser material for LED light panels. It is more impact-resistant than acrylic and can withstand higher temperatures.

- Glass: Glass is a high-quality diffuser material that provides excellent light transmission and can be designed to create unique visual effects. However, it is heavier and more fragile than plastic materials.

- Composite materials: LED light panels can also be made from composite materials, which are typically a combination of two or more materials. For example, some LED light panels may use a combination of aluminum and polycarbonate to create a lightweight yet durable frame.

Why does the light from an LED light panel look so uniform?

The light from an LED light panel appears uniform because of the way that the LEDs are arranged and the materials that are used to diffuse the light.

LED light panels typically consist of a grid of individual LEDs that are evenly spaced and aligned to provide even illumination across the entire surface of the panel. This means that each LED is contributing to the overall light output, and there are no gaps or dark spots between the LEDs that could cause uneven lighting.

In addition, LED light panels often use diffuser materials, such as acrylic or polycarbonate, to spread the light evenly across the panel. These materials are designed to scatter the light in all directions, which helps to eliminate any hotspots or shadows and create a smooth, uniform lighting effect.

The combination of evenly spaced LEDs and diffuser materials helps to create a consistent and uniform light output across the entire surface of the LED light panel. This makes them ideal for applications where even lighting is important, such as in photography studios, medical facilities, and retail environments.

What colours temperatures can LED light panels produce?

LED light panels can produce a wide range of color temperatures, which are typically measured in Kelvin (K). Here are some of the most common color temperatures produced by LED light panels:

- Warm white (2700K-3000K): This color temperature produces a warm, yellowish light that is similar to traditional incandescent bulbs. It is often used in residential and hospitality settings to create a cozy and inviting atmosphere.

- Neutral white (3500K-4100K): This color temperature produces a neutral, slightly cool light that is often used in commercial settings such as offices, classrooms, and retail stores.

- Cool white (5000K-6500K): This color temperature produces a bright, cool light that is often used in industrial settings, such as warehouses and factories, as well as in healthcare and education environments.

- Daylight (6500K+): This color temperature produces a bright, blue-white light that is similar to natural daylight. It is often used in settings where color accuracy and clarity are important, such as in art studios and photography labs.

Some LED light panels also offer adjustable color temperatures, which allow you to choose the color temperature that best suits your needs. This feature can be particularly useful in settings where the lighting needs to be adjusted to different tasks or activities.

What standard sizes do LED light panels come in?

While LED light panels can come in a variety of sizes depending on the manufacturer and application, there are some common standard sizes that are widely available in the market. Here are some of the most common standard sizes for LED light panels:

- 1x1 ft: These LED light panels measure approximately 1 foot (30 cm) in width and height, and are often used in smaller-scale applications such as photography, videography, and product displays.

- 2x2 ft: These LED light panels measure approximately 2 feet (60 cm) in width and height, and are often used in commercial and residential settings for general lighting purposes.

- 1x4 ft: These LED light panels measure approximately 1 foot (30 cm) in width and 4 feet (120 cm) in length, and are often used in commercial and industrial settings for high-output lighting applications.

- 2x4 ft: These LED light panels measure approximately 2 feet (60 cm) in width and 4 feet (120 cm) in length, and are often used in commercial and industrial settings for high-output lighting applications.

Some LED light panel manufacturers can also provide custom sizes based on the specific needs of the application.

What are the different types of LED light panels?

A comprehensive list of the types of LED light panels includes:

- Edge-lit LED light panels

- Back-lit LED light panels

- Direct-lit LED light panels

- Tunable white LED light panels

- RGB LED light panels

- Flexible LED light panels

- Outdoor LED light panels

- High-CRI LED light panels

- Low-voltage LED light panels

- Retrofit LED light panels

- Surface-mount LED light panels

- Recessed LED light panels

- Pendant LED light panels

- Curved LED light panels

- Round LED light panels

- Dimmable LED light panels

- Emergency LED light panels

- Wireless LED light panels

- Wi-Fi-enabled LED light panels

- Bluetooth-enabled LED light panels

- DMX-controlled LED light panels

- DALI-controlled LED light panels

- Zigbee-controlled LED light panels

- Smart LED light panels

- Low-glare LED light panels

- High-efficiency LED light panels

- Low-profile LED light panels

- Ultra-thin LED light panels

- Waterproof LED light panels

- Dust-proof LED light panels

- Explosion-proof LED light panels

- High-brightness LED light panels

- Low-brightness LED light panels

- High-contrast LED light panels

- High-reliability LED light panels

- High-temperature LED light panels

- High-luminosity LED light panels

- High-density LED light panels

- High-angle LED light panels

Where are LED panels used?

LED light panels are used in a wide range of applications due to their versatility, energy efficiency, and uniform illumination. Here are some common places where LED light panels are used:

- Offices and commercial buildings: LED light panels are commonly used in offices and commercial buildings for general lighting purposes due to their uniform illumination and energy efficiency.

- Educational institutions: LED light panels are used in schools and universities for their energy efficiency, durability, and low maintenance requirements.

- Healthcare facilities: LED light panels are used in hospitals, clinics, and other healthcare facilities due to their high color rendering index (CRI) and ability to produce a range of color temperatures that can simulate natural light.

- Retail stores: LED light panels are used in retail stores for accent lighting, task lighting, and general lighting purposes due to their ability to produce high-quality light and enhance the appearance of products.

- Art galleries and museums: LED light panels are used in art galleries and museums for their ability to produce high-quality light with excellent color accuracy, low heat output, and low ultraviolet (UV) emissions that can damage artworks.

- Hotels and hospitality venues: LED light panels are used in hotels and other hospitality venues for general lighting, task lighting, and accent lighting purposes due to their low energy consumption, long lifespan, and aesthetic appeal.

- Residential homes: LED light panels are used in residential homes for their energy efficiency, versatility, and low maintenance requirements. They can be used for general lighting, task lighting, and accent lighting purposes.

- Entertainment venues: LED light panels are used in concert halls, theaters, and other entertainment venues for their ability to produce high-quality light with excellent color accuracy and low heat output.

- Transportation: LED light panels are used in automobiles, airplanes, and other forms of transportation for their energy efficiency and low heat output.

- Sports facilities: LED light panels are used in sports facilities for their ability to produce high-quality light with excellent color accuracy and uniform illumination.

- Outdoor lighting: LED light panels are used for outdoor lighting applications such as street lighting, parking lot lighting, and security lighting due to their energy efficiency and long lifespan.

- Industrial facilities: LED light panels are used in warehouses, factories, and other industrial facilities for their durability, low maintenance requirements, and ability to withstand harsh environments.

How much energy can LED panels save?

LED light panels are highly energy-efficient compared to traditional lighting technologies, such as incandescent and fluorescent lights. They can save a significant amount of energy and reduce electricity bills. The amount of energy saved depends on the wattage and operating hours of the LED light panel, as well as the type of lighting it replaces.

On average, an LED light panel can save up to 50% to 70% of energy compared to fluorescent lights, and up to 90% compared to incandescent lights. For example, a 2x2 LED light panel with a wattage of 40 watts can replace a traditional 2x2 fluorescent light fixture with a wattage of 80 watts or more, resulting in energy savings of up to 50%.

In addition to energy savings, LED light panels have a longer lifespan than traditional lighting fixtures. They can last up to 50,000 hours or more, which reduces maintenance costs and further enhances their energy-saving benefits.

LED light panels also produce less heat than traditional lighting fixtures, which can result in additional energy savings from reduced cooling costs.

What are the advantages and disadvantages of LED light panels?

LED light panels offer many advantages over traditional lighting technologies, but there are also some disadvantages to consider. Here are some of the advantages and disadvantages of LED light panels:

Advantages:

- Energy-efficient: LED light panels use significantly less energy than traditional lighting technologies, which can result in lower energy bills and reduced carbon emissions.

- Long lifespan: LED light panels can last up to 50,000 hours or more, which reduces maintenance costs and enhances their energy-saving benefits.

- Low heat output: LED light panels produce less heat than traditional lighting fixtures, which can result in additional energy savings from reduced cooling costs.

- Uniform illumination: LED light panels produce uniform illumination with no flicker, which makes them ideal for applications where visual comfort is important.

- Aesthetic appeal: LED light panels are sleek, modern, and can be customized to fit a variety of design aesthetics.

- Low maintenance requirements: LED light panels require minimal maintenance, such as periodic cleaning, compared to traditional lighting fixtures.

Disadvantages:

- High upfront cost: LED light panels are more expensive upfront than traditional lighting fixtures, although the long-term energy savings and lifespan can offset this cost.

- Color accuracy: Some LED light panels may not have the same color accuracy as traditional lighting technologies, although high-quality LED light panels can produce excellent color accuracy.

- Heat dissipation: Poor heat dissipation can reduce the lifespan and efficiency of LED light panels, so proper ventilation is important.

- Blue light hazard: Some LED light panels may emit blue light, which can disrupt sleep patterns and cause other health issues, although this can be mitigated with proper color temperature selection or additional filtering.

- Dimming compatibility: Some LED light panels may not be compatible with traditional dimming systems, so additional equipment or systems may be required for dimming capabilities.

How do I choose an LED panel?

Choosing an LED light panel can seem overwhelming with the variety of options available in the market. Here are some factors to consider when choosing an LED light panel:

- Size: Consider the size of the space where the LED light panel will be installed and choose an appropriate size. LED light panels come in various sizes, from 1x1 foot to 4x4 feet.

- Wattage: LED light panels have different wattages, which affect their brightness and energy efficiency. Choose a wattage that provides sufficient illumination for your needs while being energy-efficient.

- Color temperature: LED light panels can produce different color temperatures, ranging from warm white to cool white. Choose a color temperature that suits the application and ambiance of the space.

- CRI (Color Rendering Index): CRI measures the ability of a light source to accurately render colors. Look for LED light panels with a high CRI (above 80) for better color accuracy.

- Dimming capabilities: If you require dimming capabilities, make sure to choose an LED light panel that is compatible with dimming systems. Not all LED light panels are dimmable, so be sure to check.

- Lifespan: LED light panels have longer lifespans compared to traditional lighting fixtures, which can reduce maintenance costs. Look for LED light panels with longer lifespans for better value for money.

- Price: LED light panels can vary in price depending on the quality, size, and features. Consider your budget and look for LED light panels that offer good value for money.

- Brand and warranty: Choose reputable brands that offer warranties for their products. This can ensure quality and provide peace of mind in case of any issues with the LED light panel.

What are some common problems that are found with LED light panels?

While LED light panels are generally reliable and long-lasting, they may still encounter some problems. Here are some common problems that are found with LED light panels:

- Flickering: This is when the LED light panel flashes on and off quickly. This can be caused by a faulty driver, poor wiring, or voltage fluctuations.

- Color shift: Over time, some LED light panels may shift in color, meaning they may produce different hues than what was originally intended. This can be caused by changes in temperature or humidity, poor manufacturing, or a lack of proper calibration.

- Glare: Some LED light panels may produce glare, which can be uncomfortable and affect visibility. This can be caused by the placement of the LED light panel, the type of diffuser used, or the brightness of the LED light panel.

- Dimming issues: LED light panels that are not compatible with dimming systems may experience issues with flickering or inconsistent dimming.

- Overheating: LED light panels generate heat, and if not properly designed, may overheat, which can lead to decreased lifespan or damage to the LED light panel.

- Poor light distribution: Some LED light panels may have uneven light distribution, which can create shadows or hot spots.

- Color accuracy: Some LED light panels may not accurately reproduce colors due to a low Color Rendering Index (CRI).

If you encounter any of these issues with your LED light panel, it is best to consult with a professional to diagnose and fix the problem. Regular maintenance and proper installation can also help prevent some of these issues from occurring.

How long do LED light panels last?

LED light panels are known for their long lifespan compared to traditional lighting options. The lifespan of an LED light panel depends on several factors, including its quality, usage, and environment. However, on average, LED light panels can last anywhere from 50,000 to 100,000 hours, which is significantly longer than incandescent and fluorescent bulbs.

To put this into perspective, if an LED light panel is used for 8 hours a day, it can last up to 17 years before needing to be replaced. This long lifespan not only reduces maintenance costs but also reduces the environmental impact of lighting by reducing the amount of waste generated by discarded bulbs.

It's important to note that some LED light panels may gradually lose brightness over time, but this process is very slow and generally not noticeable until the light panel is near the end of its lifespan. Regular cleaning and maintenance can also help extend the lifespan of an LED light panel.

Can LED light panels be dimmed?

Yes, LED light panels can be dimmed using a dimmer switch or controller. Unlike traditional incandescent bulbs, which can be dimmed by reducing the voltage supplied to them, LED light panels require a specialized dimmer switch or controller that is designed to work with LED technology.

There are two main types of LED dimming technologies: pulse width modulation (PWM) and constant current reduction (CCR). PWM dimming works by rapidly switching the LED on and off at a rate that is too fast to be perceived by the human eye, while CCR dimming reduces the current supplied to the LED to lower its brightness.

It's important to note that not all LED light panels are compatible with dimming, and it's important to check the specifications of your light panel to ensure that it can be dimmed. Additionally, the type of dimmer switch or controller you use must be compatible with the LED light panel you are using.

What is Color Rendering Index (CRI) and why is it important for LED light panels?

Color Rendering Index (CRI) is a measure of how accurately a light source can reveal the true colors of objects compared to natural sunlight. The CRI is a scale from 0 to 100, with a higher CRI indicating that the light source can better reproduce colors accurately.

For LED light panels, the CRI is an important factor to consider because it can affect how colors appear in the illuminated environment. A high CRI is generally desirable for applications where color accuracy is important, such as in surgery, art studios, photography studios, or museums.

LED light panels with a CRI of 80 or above are considered to have good color rendering properties, while LED light panels with a CRI of 90 or above are considered to have excellent color rendering properties. However, it's important to note that a high CRI may come at the expense of light output, as the LED light panel may require additional phosphors to produce more accurate colors.

What is the difference between a surface-mounted LED light panel and a recessed LED light panel?

The main difference between surface-mounted LED light panels and recessed LED light panels is how they are installed and mounted.

Surface-mounted LED light panels are installed on the surface of a ceiling or wall and are visible from the outside. They usually come with mounting brackets or clips that allow them to be easily mounted to the surface. These types of LED light panels are ideal for applications where there is no access to the ceiling or where a more contemporary or modern look is desired.

Recessed LED light panels, on the other hand, are installed within a ceiling or wall and are not visible from the outside. They require a hole to be cut in the ceiling or wall where the light panel is inserted. They typically come with mounting brackets or clips that are used to secure them within the ceiling or wall. These types of LED light panels are ideal for applications where a sleek, unobtrusive appearance is desired, such as in commercial or residential spaces.

How do you choose the appropriate mounting option for a LED light panel?

Choosing the appropriate mounting option for a LED light panel will depend on the specific application and the characteristics of the space in which it will be installed. Here are some factors to consider when selecting the mounting option:

- Ceiling height: If the ceiling is high, a recessed mounting option may be appropriate as it will not take up valuable ceiling space. If the ceiling is low, a surface mount may be a better choice as it will not require cutting into the ceiling.

- Access to electrical wiring: If there is no access to electrical wiring above the ceiling, a surface mount or suspension mount may be more appropriate than a recessed mount that requires electrical work.

- Desired light distribution: Surface mounted LED light panels can provide a more diffuse light distribution, while recessed panels can provide a more concentrated and focused light.

- Aesthetics: Surface mounted LED light panels can be more visible and may not be as aesthetically pleasing as recessed panels that blend seamlessly into the ceiling.

- Maintenance: If the LED light panel requires frequent maintenance or replacement, a surface mount or suspension mount may be more appropriate as they are easier to access than recessed mounts that require ceiling access.

What is the difference between an edge-lit LED light panel and a back-lit LED light panel?

The main difference between an edge-lit LED light panel and a back-lit LED light panel is how the light is distributed across the panel.

An edge-lit LED light panel uses LEDs that are located on the edge of the panel, which shine light towards the center of the panel. The light is then diffused evenly across the surface of the panel using a light guide plate or diffuser. Edge-lit LED light panels are generally thinner and lighter in weight than back-lit LED light panels, and they are often used in applications where a slim profile and even illumination are important, such as in retail displays or illuminated signs.

A back-lit LED light panel, on the other hand, uses LEDs that are located behind the panel, shining towards the front of the panel. The light is then diffused across the surface of the panel using a diffuser. Back-lit LED light panels are often used in applications where high brightness and uniform illumination are important, such as in commercial or industrial lighting applications.

In terms of energy efficiency, edge-lit LED light panels are generally more efficient than back-lit LED light panels, as they use fewer LEDs to achieve the same level of illumination. However, back-lit LED light panels are generally more robust and have a longer lifespan than edge-lit LED light panels, as the LEDs are typically more protected from damage and wear.

How do you install an LED light panel?

The specific steps for installing an LED light panel will vary depending on the type of panel and the installation location, but the following are some general guidelines that apply to most installations:

- Determine the installation location: Choose the location where the LED light panel will be installed, taking into account factors such as accessibility, power source, and mounting options.

- Prepare the installation area: Clear the area of any debris, and ensure that the surface is clean, dry, and flat.

- Install the mounting hardware: If the LED light panel requires mounting hardware, such as brackets or clips, install them according to the manufacturer's instructions. Be sure to use appropriate screws, anchors, or other hardware to secure the mounting hardware to the surface.

- Connect the wiring: If the LED light panel requires wiring, connect it to a power source, following the manufacturer's instructions. If you are not comfortable working with electrical wiring, it is recommended that you hire a licensed electrician to perform this step.

- Install the LED light panel: Depending on the type of panel, you may need to insert it into a recessed opening or mount it directly to the surface using the mounting hardware. Carefully position the panel and ensure that it is level and secure.

- Test the installation: Turn on the power to the LED light panel and ensure that it is working properly. If there are any issues, consult the manufacturer's instructions or contact a qualified technician for assistance.

- Finish the installation: Once the LED light panel is properly installed and functioning, finish any remaining steps, such as attaching a diffuser or trim piece.

It's important to follow the manufacturer's instructions carefully when installing an LED light panel, and to ensure that all safety precautions are taken when working with electrical wiring. It is essential that you hire a qualified professional to perform the installation.

What tools do you need to install an LED light panel?

The following are some tools that are commonly used for LED light panel installations:

- Measuring tape: To measure the dimensions of the installation area and ensure proper alignment of the LED light panel.

- Drill and drill bits: To create holes for mounting hardware or wiring.

- Screwdriver: To install screws or other hardware.

- Wire stripper and wire connectors: If the LED light panel requires wiring, you will need a wire stripper to remove the insulation from the wires and wire connectors to join the wires together.

- Level: To ensure that the LED light panel is installed level and straight.

- Safety equipment: Depending on the installation location, you may need safety equipment such as gloves, safety glasses, and a ladder.

How do you wire an LED light panel?

The following are some general guidelines that apply to most installations:

- Turn off the power: Before you begin wiring, make sure the power to the installation area is turned off at the circuit breaker or fuse box.

- Strip the wire: Use a wire stripper to remove the insulation from the wires of the LED light panel and the power source. Be sure to follow the manufacturer's instructions for the specific wire gauge and type.

- Connect the wires: Connect the wires of the LED light panel to the corresponding wires of the power source. This may involve twisting the wires together and securing them with wire connectors or using a plug-in connector. Be sure to follow the manufacturer's instructions for the specific connection method.

- Test the connection: Turn the power back on and test the connection by turning on the LED light panel. Ensure that it is working properly and that there are no loose connections or exposed wires.

- Secure the wires: Once the connection has been tested and is working properly, secure the wires using cable ties or wire clips to prevent them from becoming loose or tangled.

What are some common installation mistakes to avoid with LED light panels?

Here are some common installation mistakes to avoid with LED light panels:

- Incorrect wiring: Make sure to follow the manufacturer's instructions carefully when wiring the LED light panel. Wiring the panel incorrectly can cause damage to the panel or pose a safety hazard.

- Overloading the circuit: LED light panels consume less power than traditional lighting options, but it's still important to ensure that the circuit can handle the electrical load. Overloading the circuit can cause the circuit breaker to trip or damage the LED light panel.

- Improper mounting: Make sure to use the appropriate mounting hardware and follow the manufacturer's instructions for mounting the LED light panel. Improper mounting can cause the panel to fall or become damaged.

- Insufficient support: LED light panels can be heavy, so it's important to ensure that they are properly supported. Using insufficient support can cause the panel to sag or become damaged.

- Improper spacing: Make sure to space the LED light panels appropriately to ensure that they provide even lighting. Improper spacing can result in dark spots or overly bright areas.

- Forgetting to test the installation: Before finishing the installation, make sure to test the LED light panel to ensure that it is working properly. This will help you identify and correct any issues before finishing the installation.

Can LED light panels be used outdoors?

Yes, LED light panels can be used outdoors, but it's important to choose an LED panel that is specifically designed for outdoor use. Outdoor LED light panels are designed to withstand exposure to weather conditions such as rain, wind, and extreme temperatures.

When choosing an outdoor LED light panel, consider the following factors:

- IP rating: Look for a panel with a high IP rating, such as IP65 or higher. The IP rating indicates the level of protection the panel provides against dust and water.

- Temperature range: Make sure the LED panel is designed to operate within the temperature range of your outdoor environment. Extreme temperatures can affect the performance and lifespan of the panel.

- Mounting options: Choose an LED panel that can be securely mounted in your outdoor environment. Some panels may require additional mounting hardware or accessories for outdoor use.

- Power supply: Make sure the LED panel is compatible with your outdoor power supply. Some panels may require a different voltage or type of power supply than indoor panels.

It's also important to follow the manufacturer's instructions carefully when installing and using an outdoor LED light panel.

How do LED light panels compare to fluorescent lights in terms of energy efficiency?

LED light panels are generally more energy-efficient than fluorescent lights. Here are some reasons why:

- Lower energy consumption: LED light panels consume significantly less energy than fluorescent lights. LED panels can save up to 50-60% energy compared to fluorescent lights.

- Longer lifespan: LED light panels have a much longer lifespan than fluorescent lights. They can last up to 50,000 hours or more, compared to fluorescent lights, which have a lifespan of 10,000 to 15,000 hours. This means fewer replacements and less energy used in manufacturing, transportation, and disposal.

- More efficient use of energy: LED light panels use energy more efficiently because they convert a higher percentage of energy into light, while fluorescent lights generate more heat. This makes LED panels more efficient and cost-effective in terms of energy consumption.

- Instant turn-on: LED light panels turn on instantly, while fluorescent lights require time to warm up and reach their full brightness. This means less energy wasted during start-up time.

How do you clean an LED light panel?

Cleaning an LED light panel is important to ensure that it functions properly and provides optimal lighting. Here are the steps to clean an LED light panel:

- Turn off the power: Before cleaning the LED light panel, turn off the power supply to avoid any electrical accidents.

- Remove the panel cover: If your LED light panel has a removable cover, gently remove it to access the surface of the panel. If the panel cover is not removable, skip this step.

- Use a soft cloth: Use a clean, dry, and soft cloth to wipe the surface of the LED panel gently. Do not use any abrasive cleaners, solvents, or chemicals, as they can damage the panel's surface.

- Clean the frame: If the LED panel has a frame or border, use a mild detergent solution to clean it. Dip a soft cloth into the solution, wring it out, and then wipe the frame gently.

- Reinstall the panel cover: If you removed the panel cover in step 2, reattach it gently.

- Turn on the power: Turn on the power supply and verify that the LED light panel is working properly.

It's important to clean LED light panels regularly to maintain optimal performance and to ensure that they last longer.

What is the difference between an RGB LED light panel and a white LED light panel?

The main difference between an RGB LED light panel and a white LED light panel is the range of colors they can produce.

A white LED light panel produces a white light that is similar to natural daylight, with a color temperature typically ranging from 2700K to 6500K. The color temperature is a measure of how warm or cool the light appears, with lower values indicating warmer colors and higher values indicating cooler colors. White LED light panels are commonly used in commercial and residential applications, such as office lighting, task lighting, and general indoor lighting.

On the other hand, an RGB LED light panel is capable of producing a wide range of colors, including red, green, blue, and any combination of these colors. RGB stands for Red, Green, and Blue, which are the three primary colors of light. By adjusting the intensity of each color, an RGB LED light panel can produce millions of different colors and shades. RGB LED light panels are commonly used in stage lighting, event lighting, and architectural lighting applications.

In addition to the range of colors produced, another difference between white and RGB LED light panels is their control systems. White LED light panels are typically controlled by a simple on/off switch or a dimmer switch. In contrast, RGB LED light panels require a more complex control system to adjust the intensity and color of the light, such as a lighting controller or a DMX system.

What is the difference between a high-output LED light panel and a low-output LED light panel?

The main difference between a high-output LED light panel and a low-output LED light panel is the amount of light they produce.

High-output LED light panels are designed to produce a large amount of light, typically ranging from 4,000 to 20,000 lumens or more. They are ideal for applications where a bright and powerful light source is required, such as in large commercial or industrial spaces, sports facilities, or outdoor areas. High-output LED light panels are often used as a replacement for traditional HID (high-intensity discharge) or fluorescent lighting systems, as they provide similar levels of brightness while consuming less energy and lasting longer.

Low-output LED light panels, on the other hand, are designed to produce a lower amount of light, typically ranging from 500 to 3,000 lumens. They are ideal for applications where a softer and more subtle light is desired, such as in residential or hospitality settings, art galleries, or museums. Low-output LED light panels are often used as a decorative or accent lighting source, as they can be easily dimmed or adjusted to create different lighting effects.

Another difference between high-output and low-output LED light panels is their power consumption and heat output. High-output LED light panels typically consume more power and generate more heat than low-output LED light panels, due to the larger number of LEDs and the higher wattage. As a result, high-output LED light panels may require additional cooling or ventilation systems to maintain optimal performance and prevent overheating.

How do you select the right color temperature for your LED light panel?

Choosing the right color temperature for your LED light panel depends on several factors, including the intended use of the space, personal preferences, and the overall design aesthetic.

Color temperature is measured on the Kelvin (K) scale and typically ranges from warm (2700K-3000K) to neutral (3500K-4000K) to cool (5000K-6500K). Here are some tips to help you select the right color temperature for your LED light panel:

- Consider the intended use of the space: The color temperature you choose should be appropriate for the function of the space. For example, a warm color temperature (2700K-3000K) is often used in residential settings, as it creates a cozy and inviting atmosphere. A cool color temperature (5000K-6500K) is often used in commercial or industrial settings, as it provides a bright and stimulating environment.

- Determine the color rendering requirements: Color rendering is the ability of a light source to accurately reproduce colors. If color rendering is important for your application, you should select a color temperature that provides good color rendering. A color temperature of 4000K or higher is typically recommended for applications where color rendering is important, such as art galleries or retail stores.

- Consider personal preferences and design aesthetics: The color temperature you choose should also reflect your personal preferences and the overall design aesthetic of the space. For example, a warm color temperature may be more suitable for a traditional or rustic setting, while a cool color temperature may be more suitable for a modern or contemporary setting.

- Test different color temperatures: If you are unsure about which color temperature to choose, you can test different options before making a final decision. Many LED light panel manufacturers offer sample kits that allow you to compare different color temperatures in your own space.

Are there any safety concerns when using LED light panels?

When used and installed properly, LED light panels are generally safe to use. However, there are some safety concerns that should be taken into consideration when using LED light panels.

- Electrical safety: It is important to follow proper electrical safety practices when installing and using LED light panels. This includes ensuring that the wiring is installed correctly and that the power source is turned off before installation. It is also recommended to hire a qualified electrician to install the light panel.

- Heat dissipation: LED light panels can generate heat, so it is important to ensure that they are properly ventilated and that there is adequate space around the fixture. This will help prevent the LED panels from overheating and potentially causing a fire hazard.

- Eye safety: LED light panels emit bright light and can cause eye strain or discomfort if they are too bright or not properly shielded. It is important to use LED light panels with the appropriate brightness for the intended use, and to ensure that they are properly shielded to prevent direct exposure to the eyes.

- Environmental safety: LED light panels contain electronic components and should be disposed of properly according to local regulations. It is recommended to recycle LED light panels instead of disposing of them in the trash.

Are there any Australian government or industry regulations regarding the use of LED light panels?

Yes, there are several Australian government and industry regulations regarding the use of LED light panels. Here are some of the key regulations:

- Electrical safety: LED light panels must comply with Australian electrical safety standards. This includes compliance with the Electrical Equipment Safety System (EESS), which sets out requirements for the safety and performance of electrical equipment.

- Energy efficiency: LED light panels must comply with the Minimum Energy Performance Standards (MEPS) set out by the Australian government. This means that they must meet minimum energy efficiency standards to help reduce energy consumption and greenhouse gas emissions.

- Environmental impact: LED light panels must comply with the Waste Electrical and Electronic Equipment (WEEE) regulations, which require the safe disposal and recycling of electronic equipment.

- Building codes: LED light panels must comply with Australian building codes, such as the National Construction Code (NCC), which sets out requirements for building design and construction.

How do you calculate the appropriate size of LED light panel for a specific room or space?

To calculate the appropriate size of LED light panel for a specific room or space, you can use the following formula:

Area of room (in square meters) x desired illuminance (in lux) = total lumen output required

To determine the area of the room, measure the length and width of the room in meters and multiply them together to get the area in square meters.

The desired illuminance will depend on the intended use of the room. For example, a living room may require a lower illuminance of around 100-300 lux, while a kitchen or workspace may require a higher illuminance of around 500-1000 lux.

Once you have calculated the total lumen output required, you can choose an LED light panel that meets this requirement. LED light panels are typically labeled with their lumen output, so you can choose one that matches the calculated value.

It is also important to consider the distribution of light from the LED light panel. Some LED light panels have a narrow beam angle that is ideal for task lighting, while others have a wider beam angle that is better suited for general illumination. Be sure to choose an LED light panel with the appropriate beam angle for your specific needs.

Here are some general guidelines for desired illuminance for various spaces.

Residential:

Living room:

- Small living room (up to 10 square meters): 100-300 lux

- Medium living room (10-20 square meters): 300-500 lux

- Large living room (over 20 square meters): 500-700 lux

Dining room:

- Small dining room (up to 10 square meters): 300-500 lux

- Medium dining room (10-20 square meters): 500-700 lux

- Large dining room (over 20 square meters): 700-1000 lux

Kitchen:

- Small kitchen (up to 10 square meters): 500-700 lux

- Medium kitchen (10-20 square meters): 700-1000 lux

- Large kitchen (over 20 square meters): 1000-1500 lux

Bathroom:

- Small bathroom (up to 5 square meters): 300-500 lux

- Medium bathroom (5-10 square meters): 500-700 lux

- Large bathroom (over 10 square meters): 700-1000 lux

Bedroom:

- Small bedroom (up to 10 square meters): 100-300 lux

- Medium bedroom (10-20 square meters): 300-500 lux

- Large bedroom (over 20 square meters): 500-700 lux

Home office:

- Small home office (up to 10 square meters): 500-700 lux

- Medium home office (10-20 square meters): 700-1000 lux

- Large home office (over 20 square meters): 1000-1500 lux

Hallway:

- Narrow hallway: 100-200 lux

- Wide hallway: 200-300 lux

Stairs:

- Indoor stairs: 200-300 lux

- Outdoor stairs: 300-500 lux

Storage room:

- Small storage room (up to 5 square meters): 100-200 lux

- Medium storage room (5-10 square meters): 200-300 lux

- Large storage room (over 10 square meters): 300-500 lux

Commercial:

Office:

- General office space: 300-500 lux

- Reception area: 200-500 lux

- Conference room: 500-700 lux

- Copy room: 500-700 lux

- Storage room: 200-300 lux

Retail:

- Grocery store: 500-1000 lux

- Jewelry store: 750-1500 lux

- Clothing store: 750-1500 lux

- Convenience store: 300-500 lux

- Pharmacy: 500-1000 lux

Hospitality:

- Hotel lobby: 200-500 lux

- Hotel guest room: 300-500 lux

- Restaurant dining area: 300-500 lux

- Bar area: 100-200 lux

- Casino gaming area: 300-500 lux

Education:

- Classroom: 300-500 lux

- Library: 300-500 lux

- Laboratory: 500-1000 lux

- Gymnasium: 300-500 lux

- Auditorium: 500-1000 lux

Healthcare:

- Hospital patient room: 200-500 lux

- Operating room: 500-1000 lux

- Examination room: 500-1000 lux

- Waiting area: 100-200 lux

- Pharmacy: 500-1000 lux

How do you calculate the appropriate number of LED light panels for a specific room or space?

To calculate the appropriate number of LED light panels for a specific room or space, you will need to consider the size of the space, the desired illuminance level, and the lumen output of the LED light panel.

Here are the basic steps to follow:

- Measure the area of the room in square meters

- Determine the desired illuminance level for the space based on its function. As a general rule of thumb, the illuminance levels can range from 100-300 lux for residential spaces and up to 500 lux or more for commercial spaces (see above for lux levels).

- Determine the lumen output of the LED light panel. This information is typically provided in the product specifications.

- Calculate the number of LED light panels required using the following formula:

Number of LED light panels = (Area of room x Desired illuminance level) / Total lumen output of the LED light panel

For example, if you have a 20 square meter room and want an illuminance level of 200 lux, and your LED light panel has a total lumen output of 2000 lumens, the calculation would be:

Number of LED light panels = (20 sqm x 200 lux) / 2000 lumens = 2 LED light panels

It's important to note that this calculation is a general guideline and the number of LED light panels required may vary based on factors such as the height of the ceiling, the color of the walls, and the presence of natural light sources. It's always a good idea to consult with a lighting professional to ensure you have the appropriate number of LED light panels for your specific space and application.

Can LED light panels be used in cold environments, such as walk-in freezers or refrigerators?

Yes, LED light panels can be used in cold environments such as walk-in freezers or refrigerators. LED lights are known for their ability to operate in a wide range of temperatures, from very cold to very hot. However, it's important to make sure that the LED light panels you choose are rated for use in cold environments and have appropriate features to operate in those conditions.

When selecting LED light panels for use in cold environments, there are a few things to consider:

- Temperature rating: Make sure the LED light panels are rated for use in cold environments, such as those with a temperature range of -20°C to +40°C.

- Enclosure rating: Look for LED light panels with an appropriate enclosure rating, such as IP65 or higher, to protect against moisture and dust.

- Durability: Choose LED light panels that are built to withstand the harsh conditions of cold environments, such as those with a robust design and impact-resistant construction.

By selecting LED light panels that meet these criteria, you can be sure that they will perform reliably and safely in cold environments. It's also important to follow manufacturer guidelines and installation instructions to ensure proper operation and longevity of the LED light panels.

How do you choose the appropriate beam angle for a LED light panel?

Choosing the appropriate beam angle for a LED light panel depends on the specific application and the desired lighting effect. Beam angle refers to the spread of light emitted by the LED light panel, typically measured in degrees. A narrow beam angle will produce a more focused, directional light, while a wider beam angle will produce a broader, more diffuse light.

Here are some factors to consider when choosing the appropriate beam angle for a LED light panel:

- Space and environment: Consider the size and shape of the space where the LED light panel will be used, as well as the height of the ceiling and the distance between the light and the objects it will illuminate. A narrow beam angle may be more suitable for spotlighting specific objects, while a wider beam angle may be better for illuminating a larger area.

- Task or purpose: Think about the task or purpose of the lighting, as well as the desired lighting effect. For example, a narrow beam angle may be ideal for highlighting artwork, while a wider beam angle may be more suitable for general ambient lighting.

- Personal preference: Ultimately, the choice of beam angle may come down to personal preference and the desired aesthetics of the space.

How do you choose the appropriate IP rating (Ingress Protection rating) for a LED light panel?

Choosing the appropriate IP rating (Ingress Protection rating) for a LED light panel is important to ensure that the light panel is suitable for the environment in which it will be used. IP rating is a two-digit number that indicates the level of protection against dust, moisture, and other environmental factors.

Here are some factors to consider when choosing the appropriate IP rating for a LED light panel:

- Location and environment: Consider the location and environment in which the LED light panel will be used. If the light panel will be used in an indoor environment with no exposure to moisture or dust, a lower IP rating may be suitable. However, if the light panel will be used in an outdoor or industrial environment where it may be exposed to moisture, dust, or other harsh environmental factors, a higher IP rating is recommended.

- Level of protection required: Consider the level of protection required for your specific application. IP ratings range from IP20 (protection against solid objects greater than 12.5mm and no protection against water) to IP68 (protection against dust and water immersion up to 1 meter). The higher the IP rating, the greater the level of protection provided.

- Regulatory requirements: Be aware of any regulatory requirements or standards that may apply to your specific application. For example, certain industries such as healthcare, food processing, or hazardous environments may require specific IP ratings to ensure compliance with safety standards.

How do you choose the appropriate lumen output for a LED light panel?

Choosing the appropriate lumen output for a LED light panel depends on the intended use and the size of the space. Generally, larger spaces require higher lumen outputs to ensure adequate lighting. Here are some general guidelines for choosing the appropriate lumen output for LED light panels:

- Determine the size of the space: Measure the length and width of the space in meters. Multiply these values to determine the area in square meters.

- Determine the recommended illuminance level: Refer to recommended illuminance levels for the specific room or space. This will be measured in lux.

- Calculate the total lumen output needed: Multiply the area of the space by the recommended illuminance level in lux. This will give you the total lumen output needed for the space.

- Choose the appropriate LED light panel: Choose a LED light panel with a lumen output that meets or exceeds the total lumen output needed for the space.

What is the difference between a LED light panel and a LED troffer light?

LED light panels and LED troffer lights are both types of LED lighting fixtures commonly used in commercial, industrial, and institutional settings. While they share some similarities, there are also some important differences between the two.

LED Light Panels:

An LED light panel is a flat, thin, and typically rectangular fixture that uses a large number of small LED chips to produce even, diffuse light. The LEDs are mounted on a flat panel that is usually made of acrylic or polycarbonate material. LED light panels are often used in applications where a uniform and bright light source is needed, such as offices, classrooms, hospitals, and retail stores. They are typically recessed into the ceiling or suspended from the ceiling using a mounting kit.

LED Troffer Lights:

An LED troffer light is a rectangular lighting fixture that is typically larger and more substantial than an LED light panel. It usually has a metal housing and a lens that covers the LED chips, which are arranged in a grid pattern. LED troffer lights are designed to be installed in drop ceilings or hung from the ceiling with a suspension kit. They are often used in commercial and institutional settings such as offices, schools, hospitals, and retail stores, where bright, even lighting is required.

The main differences between LED light panels and LED troffer lights are their shape, size, and the way they distribute light. LED light panels are thin, flat, and produce a diffused light that is even and uniform. LED troffer lights, on the other hand, are larger, typically rectangular, and produce a directional light that is often more focused. Additionally, LED troffer lights are usually designed to be installed in a drop ceiling, while LED light panels can be recessed into a ceiling or suspended from it using a mounting kit.

Do LED light panels come with drivers?

Yes, the vast majority of LED light panels require a driver to operate and typically come with an integrated driver. The driver is responsible for converting the AC voltage of the electrical system to the DC voltage required by the LED light panel.

However, there are some LED light panels that may require an external driver to operate, particularly for larger or more complex installations. In these cases, the external driver would need to be selected separately based on the power requirements, voltage, current, and wattage requirements of the LED light panel.

It is important to carefully review the product information and specifications to determine if an LED light panel comes with an integrated driver or requires an external driver. Additionally, it is always a good idea to consult with a lighting professional to ensure that you have selected the appropriate driver for your LED light panel.

Can LED light panels be used for medical or surgical lighting?

Yes, LED light panels can be used for medical or surgical lighting. In fact, LED lighting technology has become increasingly popular for medical and surgical lighting applications due to its many benefits.

LED light panels provide bright, uniform lighting that can be customized to meet the specific needs of medical and surgical applications. LED lighting is energy-efficient, which can result in cost savings over traditional lighting sources. Additionally, LED lighting does not produce the heat that traditional lighting sources do, which can help to maintain a comfortable temperature in the operating room.

LED light panels can be used for a variety of medical and surgical applications, including operating room lighting, exam room lighting, and diagnostic imaging lighting. LED light panels can also be equipped with features such as color temperature adjustment, dimming capabilities, and remote control, which can make them ideal for medical and surgical lighting.

When selecting LED light panels for medical or surgical lighting applications, it is important to consider the specific needs of the application, such as the required light output, color temperature, and CRI (Color Rendering Index). It is also important to ensure that the LED light panels meet applicable standards and regulations for medical and surgical lighting, such as the ANSI/IES RP-16-10 standard for surgical lighting.