The Ultimate Guide to LED Drivers

Please note: we have Australia's largest range of LED light drivers for online shopping and wholesale purchase.

Introduction

LED lighting is becoming increasingly popular for a number of reasons. LED lights are generally safer and more resilient than other lighting fixtures, and also consume less energy and last far longer. So, it's easy to see why they are such a good choice.

In order to work properly, LED lights need a driver. What's a driver, you may well ask? Well, simply put, it's an electrical device that supplies the power needed to run the lights. If you're not completely familiar with these marvels of modern lighting here is a guide to explain all you need to know.

What is an LED Driver?

An LED driver (also known as an LED light driver) is an instrument that transfers power to an LED light or an array of LED chips. It converts the mains 240V power into the correct voltage and current that is usable by the LED light.

Do all LED lights need LED drivers?

The answer is yes, but it is extremely important to understand that some LED lights already come with LED drivers built in, and some don't. Those with LED drivers built in will be rated 240V and can be connected directly to the 240V mains power. Those without LED drivers built in (called low voltage lights) will be rated 12V or 24V, and will require an external LED driver to be connected between the 240V power and the LED light. A guide on how to connect low voltage lighting can be found on Installing Low Voltage Garden Lighting.

How do LED drivers work?

An LED driver provides the appropriate current to correctly power the LED light. The self-contained LED driver is able to meet the demands of the light because its electrical properties alter along with temperature. By converting power into the most appropriate voltage, the driver will power the light properly. Without the correct driver, the light could become too hot or unstable for use.

The LED driver also typically includes various protection features to ensure that the LED is not damaged due to overvoltage, overcurrent, or other electrical issues. This may include short-circuit protection, thermal protection, and other safety features.

What are the two main types of LED drivers?

The main two types of LED drivers are constant current drivers and constant voltage drivers. Both supply power to the LED fixtures, but work differently depending on the kind of lights you plan to use.

Constant current drivers work by supplying a steady flow of electrical current to the LED. The driver will adjust the voltage supplied to the LED in order to maintain the specified current level. This type of driver is commonly used in applications where it is important to maintain consistent brightness levels, such as in commercial or industrial lighting.

Constant voltage drivers work by supplying a steady voltage to the LED. This type of driver is commonly used in applications where multiple LEDs are connected in series or parallel, and it is necessary to maintain a consistent voltage level across all of the LEDs.

What are the other types of LED drivers?

Pulsed LED Drivers: These drivers supply a pulsed voltage to the LED to achieve high brightness.

Switched-Mode LED Drivers: These drivers use a switching circuit to regulate the current to the LED.

AC LED Drivers: These drivers are designed to work with AC power sources, and they often include rectification and conversion circuits to convert the AC voltage to a suitable DC voltage for the LED.

Linear LED Drivers: These drivers regulate the current to the LED by dissipating excess voltage as heat, making them less efficient than switched-mode drivers.

Programmable LED Drivers: These drivers can be programmed to adjust the output current, voltage, and other parameters to match the specific needs of the LED lighting system.

What are the advantages and disadvantages of the different types of LED drivers?

Constant Current LED Drivers:

- Advantages:

- Consistent current to LED.

- Flexible LED configuration.

- Precise control over brightness.

- Operates with wide range of input voltages.

- High efficiency in high-power applications.

- Disadvantages:

- More expensive than constant voltage drivers.

- Complex circuitry increases failure risk.

- Not suitable for some low power applications.

- Requires additional thermal management.

- Limited current range.

Constant Voltage LED Drivers:

- Advantages:

- Cost-effective option.

- Simple circuitry reduces failure risk.

- Suitable for low-power applications.

- Easy to install and use.

- Widely available.

- Disadvantages:

- Limited flexibility in LED configuration.

- Poor regulation of LED current.

- Poor efficiency in high-power applications.

- Can cause LED flicker or noise.

- Limited control over brightness.

Pulsed LED Drivers:

- Advantages:

- High brightness levels.

- Efficient operation.

- Low heat generation.

- Suitable for high-speed applications.

- Can extend LED lifespan.

- Disadvantages:

- Limited control over brightness.

- Can cause LED flicker or noise.

- Requires careful thermal management.

- Limited range of input voltages.

- More complex circuitry.

Switched-Mode LED Drivers:

- Advantages:

- High efficiency.

- Precise control over current and voltage.

- Suitable for a wide range of input voltages.

- Compact and lightweight.

- Low heat generation.

- Disadvantages:

- Can cause electromagnetic interference.

- Requires careful thermal management.

- More complex circuitry.

- Limited range of input voltages.

- Requires additional filtering to reduce noise.

AC LED Drivers:

- Advantages:

- No need for additional DC power supply.

- Compact and lightweight.

- Low cost.

- Simple circuitry.

- Suitable for low-power applications.

- Disadvantages:

- Limited control over current and voltage.

- Not suitable for high-power applications.

- Limited efficiency.

- Limited range of input voltages.

- Can cause electromagnetic interference.

Linear LED Drivers:

- Advantages:

- Simple circuitry.

- Low cost.

- Low electromagnetic interference.

- Suitable for low-power applications.

- Smooth output current.

- Disadvantages:

- Low efficiency due to power dissipation.

- Limited control over brightness.

- Requires additional thermal management.

- Limited range of input voltages.

- Not suitable for high-power applications.

What type of LED drivers do indoor lights commonly use?

Indoor LED lights commonly use constant current LED drivers. This is because constant current drivers provide a steady and consistent flow of electrical current to the LED, which is important for maintaining the desired level of brightness and color temperature. Constant current drivers are also more efficient than constant voltage drivers, and they are better able to handle changes in the input voltage or current.

Additionally, constant current drivers are more commonly used in indoor lighting applications because they are better suited to driving single LEDs or small groups of LEDs.

What type of LED drivers do outdoor lights commonly use?

Outdoor LED lights commonly use constant voltage LED drivers. This is because outdoor lighting fixtures often require multiple LEDs to be connected in series or parallel, and constant voltage drivers are better suited to handling these types of configurations.

Constant voltage drivers provide a steady and consistent voltage level to the LEDs, which ensures that all of the LEDs receive the same amount of power and light output. This is important for maintaining the desired level of brightness and color temperature in outdoor lighting applications.

In addition, constant voltage drivers are typically more robust and able to handle the higher voltages and currents required by outdoor lighting fixtures. They are also better able to withstand environmental factors such as temperature fluctuations, moisture, and dust.

Can LED drivers be used to dim lights?

Yes, LED drivers can be used to dim lights. In fact, many LED drivers are specifically designed to allow for dimming functionality.

To dim LED lights, a special type of LED driver called a dimmable LED driver is used. Dimmable LED drivers include additional circuitry that allows them to receive a dimming signal and adjust the electrical current or voltage supplied to the LED accordingly.

There are several different types of dimming methods that can be used with LED drivers, including:

- Pulse Width Modulation (PWM): PWM is a common dimming method that works by rapidly turning the LED on and off at a specific frequency. By adjusting the duty cycle (the ratio of on time to off time), the perceived brightness of the LED can be controlled.

- Analog Dimming: Analog dimming works by adjusting the voltage or current supplied to the LED. This is typically done by using a potentiometer or other variable resistor to adjust the level of current or voltage.

- Digital Dimming: Digital dimming uses a digital signal, such as a 0-10V control signal or a DALI signal, to control the brightness of the LED.

Can LED drivers be used for colour correction?

Yes, LED drivers can be used for color correction in LED lighting applications. Color correction is the process of adjusting the color temperature of the LED to achieve a desired color output. LED drivers can play an important role in this process, as they control the electrical current or voltage supplied to the LED.

Color correction can be achieved in several ways, including using color filters or diffusers, adjusting the LED driver output voltage or current, or using LED drivers with specific color temperature control features.

Some LED drivers have built-in color temperature control features that allow for easy color correction. For example, some LED drivers may include a dimming function that can be used to adjust the color temperature of the LED. Other LED drivers may include adjustable output voltage or current settings that can be used to achieve the desired color temperature.

In addition, some LED drivers may be designed to work with specific types of LEDs or LED modules that have been designed for color correction. These LED modules may include additional circuitry or color correction filters that work in conjunction with the LED driver to achieve the desired color output.

Apart from dimming and colour correction, what other functions can LED drivers do?

In addition to dimming and color correction, LED drivers can perform several other important functions in LED lighting applications. Here are some examples:

- Power Conversion: LED drivers convert incoming AC or DC power to the appropriate voltage and current required by the LEDs. This is an essential function that ensures that the LED operates at the correct voltage and current levels to provide the desired light output.

- Overvoltage and Overcurrent Protection: LED drivers can include protection circuits that prevent damage to the LEDs from overvoltage or overcurrent conditions. This is important for ensuring the safety and longevity of the LED and the lighting fixture.

- Thermal Management: LED drivers can include thermal management features, such as thermal sensing and current limiting, to help prevent overheating of the LED and the driver. This can help to ensure the longevity and reliability of the LED lighting system.

- Communication: LED drivers can include communication protocols, such as DALI or DMX, that allow for remote control and monitoring of the LED lighting system. This can be useful in commercial and industrial applications where lighting needs to be adjusted or controlled remotely.

- Efficiency Optimization: LED drivers can include features that optimize the efficiency of the LED lighting system, such as power factor correction, which can help to reduce energy consumption and improve the overall efficiency of the system.

How do LED drivers impact the energy efficiency in lighting systems?

LED drivers play an important role in improving energy efficiency in lighting systems in several ways:

- Power Conversion Efficiency: LED drivers convert the incoming AC or DC power to the appropriate voltage and current required by the LED. The efficiency of this conversion process can have a significant impact on the overall energy efficiency of the lighting system. LED drivers with high power conversion efficiency can help to reduce energy consumption and operating costs.

- Power Factor Correction (PFC): LED drivers can include PFC circuits that help to improve the power factor of the lighting system. Power factor is a measure of the efficiency of the power delivery to the lighting system. A low power factor can lead to wasted energy and increased operating costs. LED drivers with PFC circuits help to improve the power factor, which can help to reduce energy consumption and improve the overall efficiency of the lighting system.

- LED Driver Efficiency: The efficiency of the LED driver itself can have a significant impact on the overall energy efficiency of the lighting system. LED drivers with high efficiency ratings can help to reduce energy consumption and operating costs.

- Dimming: LED drivers can be used to dim the LEDs, which can help to reduce energy consumption and operating costs. By dimming the LEDs, less power is consumed, and the overall energy efficiency of the lighting system is improved.

- Thermal Management: LED drivers can include thermal management features, such as thermal sensing and current limiting, that help to prevent overheating of the LED and the driver. Overheating can lead to increased energy consumption and reduced lifespan of the LED lighting system. By managing the temperature of the LED and the driver, the energy efficiency and lifespan of the lighting system can be improved.

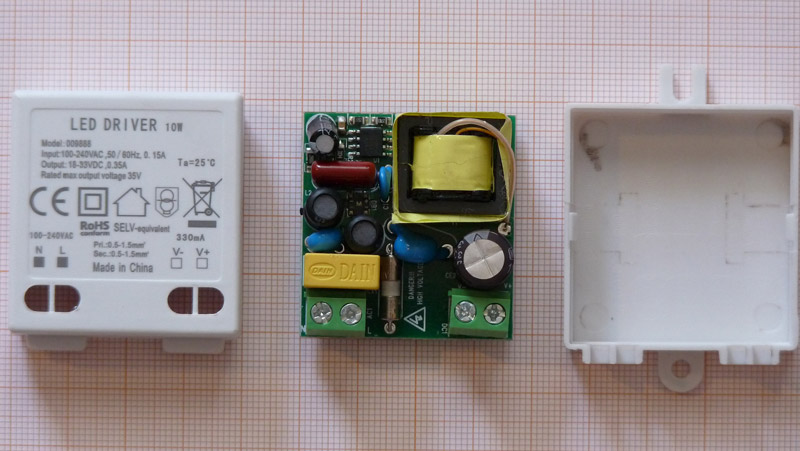

What are the components of an LED driver?

An LED driver is a complex electronic device that typically includes several key components. Here are the most common components that are typically included in an LED driver:

- Input Rectifier: This component converts the AC voltage from the power source to DC voltage. The input rectifier can be a bridge rectifier, which consists of four diodes arranged in a bridge configuration, or a single diode.

- Filter Capacitor: This component smooths out the DC voltage waveform from the input rectifier, reducing any ripple or noise in the voltage.

- Power Factor Correction (PFC) Circuit: This circuit helps to improve the power factor of the LED driver by controlling the current drawn from the AC power source.

- DC-DC Converter: This component converts the DC voltage from the input rectifier and filter capacitor to the appropriate voltage and current required by the LEDs.

- Control Circuit: This circuit controls the output voltage or current of the LED driver, and may also include features such as dimming control, thermal protection, and overvoltage and overcurrent protection.

- Output Capacitor: This component smooths out the output voltage and reduces any ripple or noise in the voltage.

- LED Load: The LED load consists of the LED or LED array that is being powered by the LED driver.

How do you select the right LED driver for your lights?

To select the right LED driver for your lights, you should consider the following factors:

- Input voltage: The LED driver should be compatible with the input voltage of your power source. You can check the voltage range of your LED lights and choose a driver with a compatible input voltage range.

- Output voltage and current: The LED driver should provide a stable output voltage and current that matches the requirements of your LED lights. Check the specifications of your LED lights to determine the required voltage and current.

- Wattage: The LED driver should have a wattage rating that matches or exceeds the total wattage of your LED lights. Make sure to calculate the total wattage of your LED lights to select an appropriate driver.

- Dimming: If you want to control the brightness of your LED lights, you should select a driver that supports dimming. Check the compatibility of the driver with the dimming system you plan to use.

- Environmental conditions: If your LED lights will be used in harsh environments, such as outdoor or industrial settings, you should choose a driver that is rated for those conditions.

- Efficiency: Select an LED driver that has high efficiency to reduce energy consumption and increase the lifespan of your LED lights.

- Type of LED driver: Choose the type of LED driver that best fits your lighting design and control requirements. For example, if you need precise control over the LED output, a programmable LED driver may be the best option.

What are the common issues to watch out for when using LED drivers?

Here are some common issues to watch out for when using LED drivers:

- Overheating: LED drivers can generate heat, which can cause the driver to malfunction or fail if not properly managed. Make sure to select a driver that is rated for the wattage of your LED lights and ensure adequate ventilation and cooling for the driver.

- Compatibility: Ensure that the LED driver is compatible with the type of LED lights you are using. Using an incompatible driver can cause flickering, poor performance, or damage to the LEDs.

- EMI and noise: LED drivers can generate electromagnetic interference (EMI) and noise, which can affect other electronic devices in the vicinity. Choose a driver with low EMI and noise ratings to avoid interference issues.

- Voltage fluctuations: If the input voltage to the LED driver fluctuates beyond the driver's specified range, it can cause the driver to malfunction or fail. Use a voltage stabilizer or surge protector to prevent voltage fluctuations.

- Wiring errors: Incorrect wiring of the LED driver can cause damage to the driver or LEDs. Ensure that the wiring is done according to the manufacturer's instructions.

- Dimming issues: If using a dimmable LED driver, ensure that it is compatible with the dimming system being used. Incompatible dimmers can cause flickering or other performance issues.

- Failure to meet regulatory standards: LED drivers must meet regulatory standards for safety and electromagnetic compatibility. Choose a driver that has been certified by the relevant regulatory bodies to ensure safety and compliance.

How do you test LED drivers for reliability and durability?

Here are some ways to test LED drivers for reliability and durability:

- Thermal testing: LED drivers generate heat during operation, which can affect their reliability and lifespan. Conduct thermal testing to evaluate the driver's ability to manage heat and ensure that it remains within safe operating temperatures.

- Voltage stability testing: LED drivers must maintain stable output voltages to prevent damage to the LEDs. Conduct voltage stability testing to ensure that the driver can maintain a stable output voltage over a range of input voltages and loads.

- Electrical safety testing: LED drivers must meet electrical safety standards to ensure safe operation. Conduct electrical safety testing to ensure that the driver complies with relevant safety standards, such as IEC 61347.

- EMI testing: LED drivers can generate electromagnetic interference (EMI) that can affect other electronic devices. Conduct EMI testing to evaluate the driver's EMI performance and ensure that it complies with relevant standards.

- Durability testing: LED drivers must be able to withstand environmental factors, such as temperature changes, humidity, and vibration. Conduct durability testing to evaluate the driver's ability to withstand these factors and ensure that it remains functional over time.

- Aging testing: LED drivers can degrade over time, affecting their reliability and performance. Conduct aging testing to evaluate the driver's performance over a long period of time and ensure that it remains reliable.

- Compliance testing: LED drivers must meet regulatory standards for safety, electromagnetic compatibility, and energy efficiency. Conduct compliance testing to ensure that the driver meets relevant regulatory standards.

How does IP rating affect choosing your LED driver?

The IP (Ingress Protection) rating of an LED driver determines its ability to withstand exposure to dust, water, and other environmental factors. The IP rating is indicated by two digits, the first digit represents the level of protection against solid objects such as dust, while the second digit represents the level of protection against liquids.

When selecting an LED driver, it's important to consider the environment in which it will be used, and choose an IP rating that matches the level of exposure to dust and water. Here are some guidelines to consider:

- Dry indoor environment: An LED driver with an IP20 rating is sufficient for use in a dry indoor environment where there is no risk of exposure to dust or water.

- Damp indoor environment: For a damp indoor environment, such as a bathroom or kitchen, an LED driver with an IP44 rating is recommended to provide protection against splashing water.

- Outdoor environment: In an outdoor environment, the LED driver should have an IP65 or higher rating to protect against exposure to rain, snow, and dust.

- Harsh industrial environment: For industrial or harsh environments, an LED driver with an IP67 or higher rating is recommended to provide maximum protection against dust and water.

Choosing an LED driver with the appropriate IP rating is essential to ensure the longevity and reliability of the driver in the specific environment it will be used in.

How does IK rating affect choosing your LED driver?

The IK rating measures the level of protection that an LED driver has against mechanical impact, such as being hit or struck by a physical object. The rating ranges from IK00 (no protection against mechanical impact) to IK10 (highest level of protection against mechanical impact).

When selecting an LED driver, the IK rating is an important consideration if the driver will be installed in an environment where it is likely to be subjected to physical impact, such as in a factory or warehouse. Here are some guidelines to consider:

- Low risk of impact: If the LED driver will be installed in a low-risk environment, such as an indoor office or retail space, an IK rating of IK04 or higher may be sufficient.

- Moderate risk of impact: In an environment with moderate risk of impact, such as a manufacturing plant or workshop, an LED driver with an IK08 rating or higher is recommended.

- High risk of impact: For environments with a high risk of impact, such as outdoor parking areas or industrial sites, an LED driver with an IK10 rating is recommended for maximum protection against mechanical impact.

Choosing an LED driver with the appropriate IK rating is important to ensure that the driver is durable and reliable in the specific environment it will be used in, and can withstand mechanical impact without compromising its performance or safety.

Which is better: AC or DC LED driver?

Both AC and DC LED drivers have their own advantages and disadvantages, and which one is better for your LED lighting project will depend on your specific needs and requirements. Here are some factors to consider when choosing between AC and DC LED drivers:

- Compatibility: LED lighting typically requires DC power to operate, which means that AC LED drivers require additional components, such as a rectifier, to convert the AC power to DC power. DC LED drivers, on the other hand, provide direct DC power to the LEDs, which can simplify the installation and reduce costs.

- Efficiency: AC LED drivers are generally less efficient than DC LED drivers, as the conversion process from AC to DC power results in some power loss. DC LED drivers, which provide direct DC power, can operate at higher efficiencies.

- Size: AC LED drivers are typically larger than DC LED drivers due to the additional components required for AC-to-DC conversion. DC LED drivers can be smaller and more compact.

- Cost: AC LED drivers are generally less expensive than DC LED drivers, as they require fewer components and are easier to manufacture. However, the cost difference may be offset by the potential energy savings and longer lifespan of DC LED drivers.

- Safety: AC LED drivers can pose a safety risk if not properly designed and installed, as they can generate high voltages and currents. DC LED drivers, which provide lower voltage and current levels, may be safer and easier to handle.

What is the impact of LED drivers on the lifetime of LED lights?

LED drivers can have a significant impact on the lifetime of LED lights. Here are some factors to consider:

- Overdriving: Overdriving an LED driver by exceeding its rated capacity can cause the LEDs to operate at a higher temperature, which can reduce their lifespan. Using an LED driver with the appropriate capacity for the LEDs can help to ensure that they operate within safe temperature limits, which can extend their lifespan.

- Voltage fluctuations: Voltage fluctuations can occur in the power supply, which can affect the performance of the LED driver and the LEDs. Over time, these fluctuations can cause damage to the LEDs, which can reduce their lifespan. Using an LED driver with good voltage regulation can help to protect the LEDs from voltage fluctuations and extend their lifespan.

- Temperature: High temperatures can reduce the lifespan of LEDs, and the temperature of the LED driver can affect the temperature of the LEDs. Choosing an LED driver with good thermal management can help to dissipate heat and maintain safe operating temperatures for both the LED driver and the LEDs, which can extend their lifespan.

- Quality: The quality of the LED driver can have a significant impact on the lifespan of the LEDs. Using a high-quality LED driver with good components and design can help to ensure that the driver operates reliably and safely over a long period, which can extend the lifespan of the LEDs.

What does overdriving an LED driver mean and what are the impacts?

Overdriving an LED driver means operating it at a higher current or voltage than its rated capacity. This can have several impacts on the performance and lifespan of both the LED driver and the LEDs it powers:

- Reduced lifespan: Overdriving an LED driver can cause it to operate at a higher temperature, which can reduce its lifespan. This can also affect the lifespan of the LEDs it powers, as they are more sensitive to temperature than the driver.

- Reduced efficiency: Overdriving an LED driver can reduce its efficiency, as it may not be able to convert the power as effectively as it would at its rated capacity. This can result in wasted energy, which can increase operating costs and reduce the lifespan of the driver.

- Diminished performance: Overdriving an LED driver can also cause the LEDs to perform poorly, as they may not receive the appropriate amount of power or voltage. This can result in reduced brightness, flickering, or other issues that can impact the quality of the lighting.

- Safety concerns: Overdriving an LED driver can also pose a safety risk, as it can cause the driver or the LEDs to malfunction, overheat, or even fail catastrophically. This can cause damage to the surrounding environment and potentially harm people nearby.

How do you troubleshoot common issues with LED drivers?

Here are some general steps to troubleshoot common issues with LED drivers:

- Check the connections: Make sure all connections are secure and properly connected. Loose or damaged connections can cause problems with the LED driver.

- Check the power supply: Verify that the power supply is functioning properly and providing the correct voltage and current to the LED driver. A faulty power supply can cause issues with the driver.

- Check for overheating: LED drivers can overheat if they are overloaded or not designed for the specific application. Check for any signs of overheating, such as a burning smell or the driver being too hot to touch. If the driver is overheating, it may need to be replaced with one that is better suited for the application.

- Check for flickering or dimming: Flickering or dimming can indicate a problem with the LED driver, such as an overload or a faulty driver. Try reducing the load on the driver or replacing the driver to see if the problem goes away.

- Use a multimeter: A multimeter can be used to check the voltage and current output of the driver. Compare the readings to the specifications provided by the manufacturer to determine if the driver is functioning properly.

- Replace the driver: If all other troubleshooting steps have been exhausted and the problem persists, it may be necessary to replace the driver with a new one. Make sure to choose a driver that is compatible with the LEDs and the specific application.

What does power factor correction in LED drivers mean?

Power factor correction (PFC) in LED drivers refers to the process of improving the efficiency of the driver by correcting the power factor of the input current. Power factor is a measure of how efficiently an electrical system uses the power that is supplied to it. A power factor of 1.0 indicates that all the power supplied is being used efficiently, while a power factor of less than 1.0 indicates that some of the power is being wasted.

In the context of LED drivers, PFC involves using circuitry to adjust the input current waveform so that it is more sinusoidal, or in other words, closer to the ideal waveform of the AC power supply. This results in a higher power factor and improved efficiency, as less power is wasted in the form of heat or electromagnetic interference.

The benefits of power factor correction in LED drivers include:

- Reduced energy consumption: PFC helps to reduce energy consumption by improving the efficiency of the driver. This can result in lower electricity bills and reduced carbon emissions.

- Longer lifespan: PFC can also extend the lifespan of the driver and the LEDs it powers by reducing the amount of heat generated and the stress placed on the components.

- Compliance with regulations: In some countries, PFC is a mandatory requirement for electrical equipment, including LED drivers. By incorporating PFC into their products, manufacturers can ensure that they meet regulatory requirements and avoid penalties.

What a are common misconceptions about LED drivers?

Here are some common misconceptions about LED drivers:

- All LED drivers are the same: This is not true as there are many different types of LED drivers with varying specifications and features, such as constant voltage, constant current, dimming capabilities, and programmability.

- LED drivers are interchangeable: While it is possible to replace a faulty LED driver with a similar one, it is important to ensure that the replacement driver is compatible with the LED array and the specific application.

- LED drivers do not affect the lifespan of LEDs: LED drivers play a crucial role in powering and controlling LEDs, and using the wrong type or size of driver can cause premature failure of the LEDs.

- Higher wattage LED drivers are always better: Using a higher wattage LED driver than necessary can lead to overheating, reduced efficiency, and decreased lifespan of both the driver and the LEDs.

- LED drivers do not require maintenance: Like any other electronic component, LED drivers can fail over time and require replacement or repair.

- All LED drivers have power factor correction (PFC): While PFC is becoming increasingly common in LED drivers, not all drivers have this feature, and it is important to choose a driver that is appropriate for the application and complies with regulations.

What are the advantages of using multiple LED drivers in a lighting system?

There are several advantages to using multiple LED drivers in a lighting system:

- Increased flexibility: Using multiple LED drivers allows for greater flexibility in designing the lighting system. Different drivers can be used for different sections of the system, allowing for more precise control of the lighting levels, colors, and dimming.

- Redundancy: Having multiple LED drivers provides redundancy in case of driver failure. If one driver fails, the others can continue to power the remaining LEDs, minimizing downtime and maintenance costs.

- Improved efficiency: By using multiple LED drivers, it is possible to optimize the power distribution across the lighting system, reducing energy waste and increasing overall efficiency.

- Greater reliability: Using multiple LED drivers reduces the load on each driver, which can improve the reliability and lifespan of the drivers and the LEDs.

- Better thermal management: Multiple LED drivers can help to spread the thermal load across the system, reducing the risk of overheating and extending the lifespan of the LEDs and drivers.

- Scalability: Using multiple LED drivers allows for easier scalability of the lighting system. Additional drivers can be added as needed to accommodate changes in the system, without having to replace the entire system.

Are LED drivers for RGB and color-changing lighting applications different?

Yes, LED drivers for RGB and color-changing lighting applications are different from those used for single-color LEDs. RGB and color-changing LEDs require drivers that can control the color and intensity of each individual LED within the system.

RGB and color-changing LEDs typically use a combination of red, green, and blue (RGB) LEDs or a combination of RGB and white LEDs to create a range of colors. The LED driver for these types of LEDs must be able to provide independent control of the current and voltage to each individual LED, as well as provide the necessary control signals for changing the color and intensity of the LEDs.

In addition, RGB and color-changing LED drivers may also have different output voltage and current requirements compared to drivers for single-color LEDs. For example, a driver for a white LED may have an output voltage of 24V and a current of 1A, while a driver for an RGB LED system may have an output voltage of 12V and a current of 3A.

Therefore, when selecting an LED driver for RGB and color-changing lighting applications, it is important to choose a driver that is specifically designed for these types of LEDs and meets the voltage, current, and control requirements of the system.

What are DALI LED drivers and what are their benefits?

DALI stands for Digital Addressable Lighting Interface, and DALI LED drivers are LED drivers that comply with the DALI protocol. The DALI protocol is a standardized digital communication protocol specifically designed for lighting control.

The main difference between DALI LED drivers and other LED drivers is in the way they control the LEDs. DALI LED drivers use the DALI protocol, which is a standardized digital communication protocol specifically designed for lighting control. Other LED drivers may use different protocols, such as PWM (Pulse Width Modulation) or analog control.

DALI LED drivers allow for individual control and dimming of each LED in the system, whereas other LED drivers may only provide group or zone dimming. DALI LED drivers can also be easily integrated into building automation systems, allowing for centralized control and monitoring of the lighting system.

In addition, DALI LED drivers offer greater flexibility in designing and controlling the lighting system. For example, they can be used to program different lighting scenes for different times of day or activities, or to control the color temperature of the LEDs.

Another difference between DALI and other LED drivers is in their wiring requirements. DALI LED drivers use a two-wire communication bus, which can reduce the amount of wiring and infrastructure required compared to other LED drivers that may require separate control wiring.

DALI LED drivers offer several benefits:

- Increased flexibility: DALI LED drivers allow for individual control and dimming of each LED in the system, allowing for greater flexibility in designing and controlling the lighting system.

- Easy integration: DALI LED drivers can be easily integrated into building automation systems, allowing for centralized control and monitoring of the lighting system.

- Energy efficiency: By providing precise control over the lighting levels, DALI LED drivers can help to optimize energy usage and reduce energy waste.

- Scalability: DALI LED drivers can be easily scaled up or down to accommodate changes in the lighting system, without having to replace the entire system.

- Cost-effective: DALI LED drivers can be cost-effective for large lighting systems, as they can reduce the amount of wiring and infrastructure required compared to traditional lighting systems.

- Enhanced functionality: DALI LED drivers can offer additional functionality, such as color temperature control and the ability to program different lighting scenes for different times of day or activities.

What is the role of LED drivers in emergency lighting systems?

In emergency lighting systems, LED drivers play a critical role in ensuring that the emergency lighting is powered and operational in the event of a power outage or other emergency situation. LED drivers can be used in emergency lighting systems to:

- Provide backup power: LED drivers can be used to provide backup power to emergency lighting systems, ensuring that the lights remain on even in the event of a power outage.

- Control the lighting levels: LED drivers can be used to control the lighting levels of the emergency lights, ensuring that the lights are bright enough to provide adequate visibility during an emergency situation.

- Monitor the system: LED drivers can be used to monitor the emergency lighting system, providing alerts in the event of a fault or failure in the system.

- Extend the lifespan of the emergency lights: LED drivers can be used to regulate the voltage and current supplied to the LEDs, which can help to extend the lifespan of the emergency lights and reduce maintenance costs.

- Comply with safety standards: LED drivers used in emergency lighting systems must comply with safety standards such as UL 924 and IEC 61347-2-7 to ensure the reliability and safety of the system.

What is the impact of LED driver selection on color rendering index (CRI)?

The selection of LED drivers can have an impact on the color rendering index (CRI) of LED lights. CRI is a measure of how accurately a light source illuminates colors compared to a natural light source, with a higher CRI indicating better color accuracy.

LED drivers can impact the CRI of LED lights in several ways, including:

- Voltage and current regulation: LED drivers regulate the voltage and current supplied to the LEDs, which can impact the spectral output of the LEDs and, in turn, the CRI of the light.

- Dimming: LED drivers used for dimming can impact the spectral output of the LEDs and, in turn, the CRI of the light, particularly at lower light levels.

- Flicker: LED drivers that produce flicker can impact the perceived color of the light and, in turn, the CRI of the light.

- Compatibility: LED drivers that are not compatible with the LED modules used in the light fixture can impact the spectral output of the LEDs and, in turn, the CRI of the light.

Therefore, it is important to select LED drivers that are designed to work with the specific LED modules used in the light fixture and that are compatible with the desired dimming system, if applicable. Additionally, selecting LED drivers that produce low flicker and provide stable voltage and current regulation can help to maintain high CRI values in LED lighting systems.

How important is surge protection in LED driver design?

Surge protection is an important consideration in LED driver design as it helps to protect the LED lighting system from damage caused by power surges or transient voltage spikes. Surges can be caused by lightning strikes, power outages, or other electrical events, and can cause significant damage to LED lighting systems if not properly protected.

LED drivers with surge protection are designed to limit the amount of voltage that reaches the LED module during a surge event, reducing the risk of damage to the LEDs or other components in the lighting system. Surge protection can also help to increase the reliability and longevity of the LED lighting system by preventing premature failure due to surges.

Surge protection can be incorporated into LED drivers in several ways, including through the use of metal oxide varistors (MOVs), gas discharge tubes (GDTs), or other surge protection devices. It is important to choose LED drivers that are designed with surge protection appropriate for the specific application and location where the lighting system will be installed.